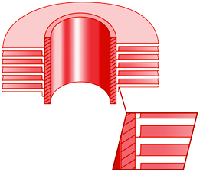

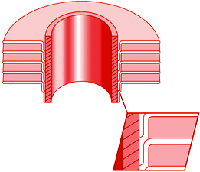

Profins is the largest manufacturer of helical high finned tube in the United Kingdom with the facility to produce in excess of 10,000 metres of quality finned tube per week.

Our

ability to draw base tube from our stock of over 1,000 tonnes allows us

to react quickly to clients' demands and to remain competitive with any

other producer worldwide. Profins' finning facility enables numerous

fin and tube material and size combinations to be manufactured. This

gives us unrivalled flexibility and allows us to react swiftly to

emergency orders.